Wheels

How hard is it to make your own wheels? Hard.

Just 3D print TPU

Wheel hubs

Casting

Ok, so you want to cast a mold anyway. Sometimes it kind of works!

My first attempt was a complicated multi-part mold. It actually worked. By designing such that I would pour to each level, add a part, pour, add, then bolt on a lid, it worked great! There were some small defects, but it fit what I had originally designed! There were a few flaws, of course.

To actually build it, I assembled it in multiple parts. My initial thought was to throw a ton of bolts into a part and then throw on a bunch of wingnuts by holding a bolt head in place with an Allen key. The Allen key design was bad from the start, so I started designing hexagon “wrenches” into the 3D prints to hold the nuts in place. This also made the bottom of the mold completely flat. The bolts were completely reusable as long as mold release was applied to their surfaces.

Later on, I switched to a single large bolt with a thick, stiff lid. This worked much better for resin with a faster setting time and greatly decreased complexity.

Sacrificial Mold

Even though you can get fancy with geometry, sometimes it’s just better to destroy your molds. 3D printing is so fast and accessible these days, it’s absolutely fine to take a hammer or a saw to your mold. You want the part trapped inside? Just go print another mold!

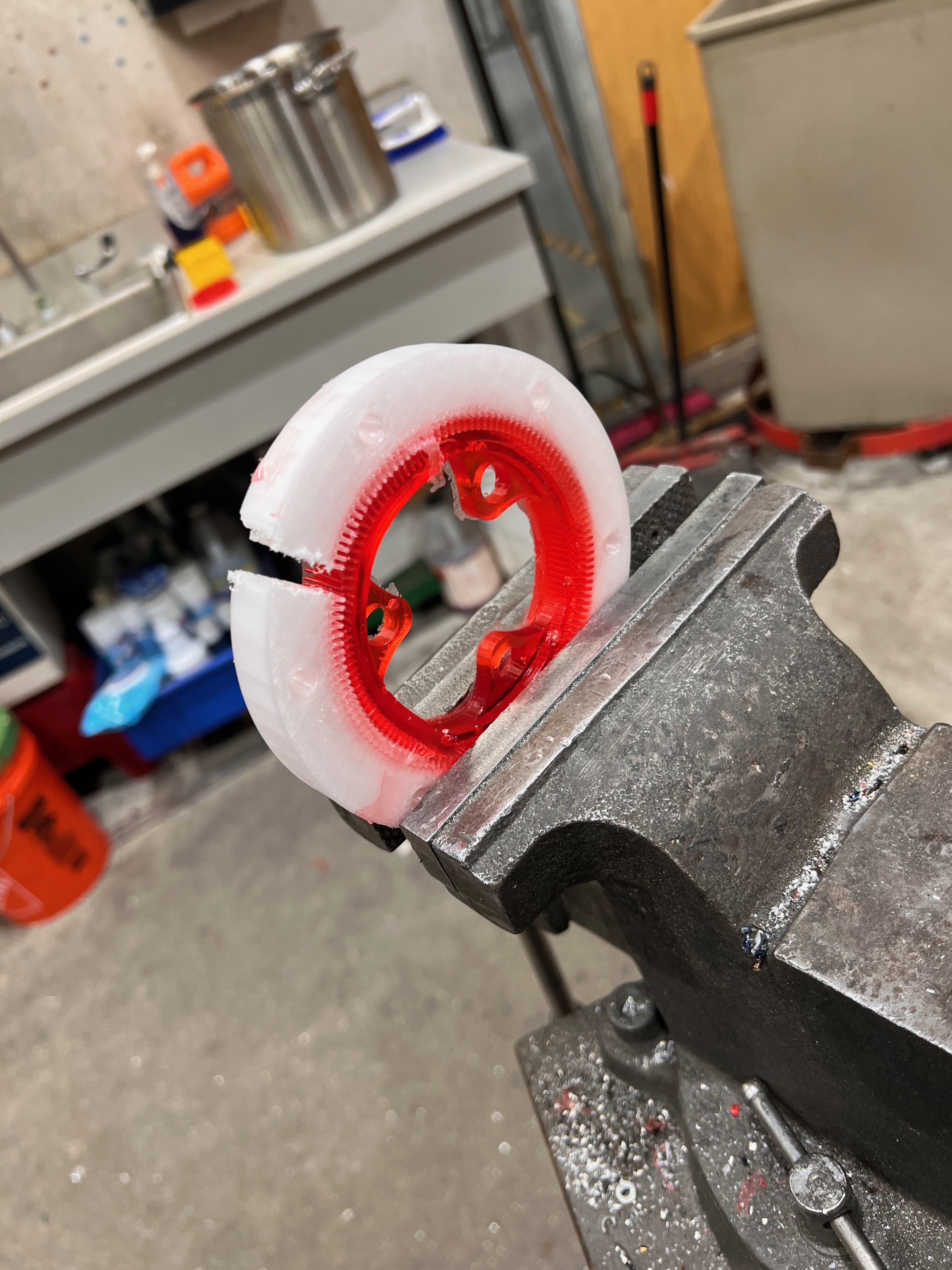

Even more, sometimes your 3D-printed molds will fail. With the cheap mixture and release I was using, sometimes designs would just not come apart. The white design was on its second use, and an error was made on the release compound. The black one had a mixture error, and two mold parts fused into unusable geometry. Both I just threw away and made another prototype.